Services and Expertise

Expert precision micro-machining of hard and extra-hard materials

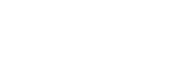

Laser machining

Laser technology has been part of our daily lives for over 40 years.

In order to keep up with this constantly-evolving technology, we need to integrate more and more efficient laser sources.

Our laser machines can machine holes ranging from 0.03 mm to 2.00 mm in diameter.

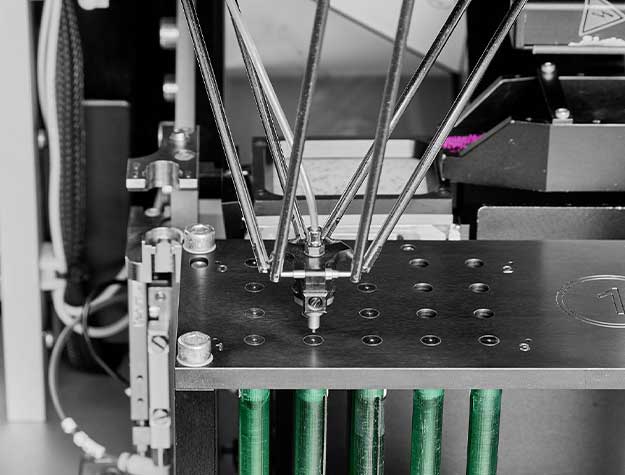

Most of our laser machines have been developed in-house.

Femtosecond laser: Aware of the need to ensure more reliable and repeatable production, the company decided, with the help of the group’s R&D department, to completely rethink the stone manufacturing process. It developed a femtolaser drilling process which achieves an excellent surface finish and a near μm accuracy of the internal hole diameter.

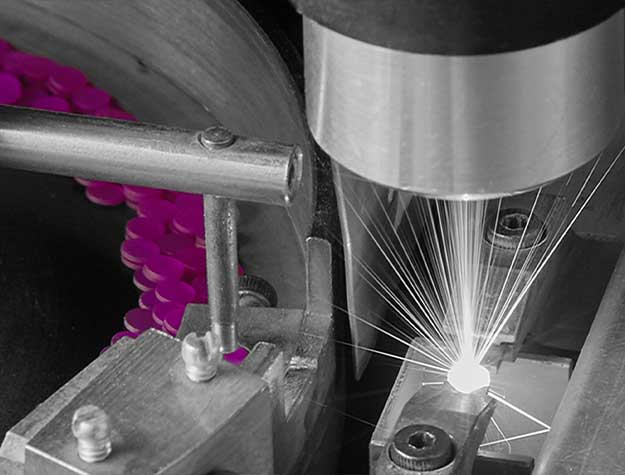

Lapping on wire

Also known as “enlarging” in the jargon of jewel-cutters, this process allows holes with diameters ranging from 0.07 mm to 2.00 mm.

Our expertise enables us to achieve a nanometric surface finish and a tolerance of a few microns.

No fewer than eight complex operations are required to achieve this result.

Turning

Turning the outer diameter is done by centreless grinding and can achieve a tolerance of ± 2 μm.

This technology and our experience mean we can achieve hole concentricities of less than 5 μm in relation to an outside diameter ranging from 0.5 mm to 5.00 mm.

Depending on the customer’s requirements, we can also use our range of tools to polish the outer diameter.

Recessing

A complete set of machines of different generations is used to machine the hole.

This machining, piece by piece, allows us to guarantee a tolerance of ± 0.050 mm in the hole diameter and ± 10 μm on the hole height.

Our range of equipment is also capable of machining a bevel or a curve on a part.

Fully digital Creusomat: To ensure repeatability and hole length of the recess, Pierhor-Gasser designed a fully numerically controlled Creusomat, replacing the old cam system. This machining tool is automatically measured and adjusted in situ to ensure a consistent recess depth.

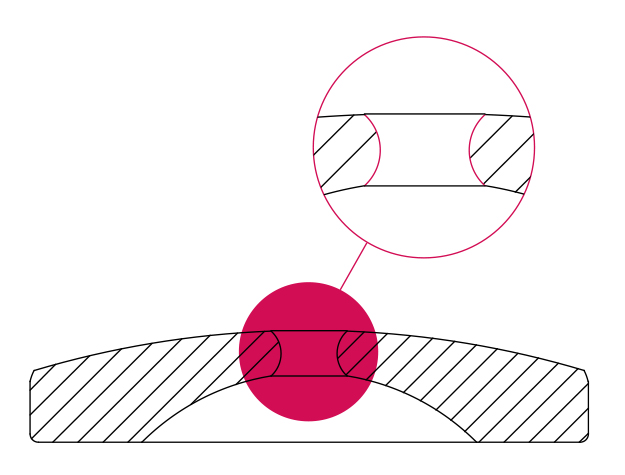

Olive-cutting

A machine inventory designed entirely in-house achieves the olive shape of a hole.

Our technology allows us to achieve tolerances of ± 2 μm for the hole diameter while guaranteeing the desired geometry and surface finish.

Olive-cutting using femto laser: The new femtolaser drilling process also allows us to olive-cut components with perfect repeatability and near μm accuracy.

Polishing

We have a complete set of machines for performing several types of operations:

- brush-polishing to achieve geometry

- grinding allows us to adjust the thickness, guaranteeing a tolerance of up to ± 5 μm

- finishing allows us to achieve mirror-polished surfaces

Engineering

Our expertise and in-depth knowledge of our processes allow us to develop our machinery.

By automating processes, building new machines, and creating or modifying tooling, we are able to offer our customers shorter lead times, impeccable quality, and a multitude of possibilities for new products.