Inkjet and Waterjet Nozzles

Precision Micro-machined Sapphire and Ruby Nozzles for Inkjet and Waterjet Heads

Pierhor-Gasser is known for its high-quality precision parts made from precious stones – sapphire and ruby. These jewel specialized components are used in various industrial applications like watchmaking. They are particularly useful in fields where precise and controlled fluid dispensing is crucial such as printing and precise waterjet systems.

Sapphire and Ruby – Application and Advantages

Gemstones sapphire and ruby are known as the hardest minerals discovered to date. Their exceptional hardness and resistance to wear make them an ideal choice for applications where durability and precision are essential.

- Sapphire: Sapphire is a single crystal form of aluminum oxide (Al2O3). It is extremely hard and has excellent chemical resistance. Sapphire nozzles are known for their durability, even when used with abrasive or corrosive fluids.

- Ruby: Ruby is a type of corundum, also made of aluminum oxide, but it gets its red color from the presence of chromium. Like sapphire, ruby is hard and resistant. Ruby nozzles are especially prized for their precision and longevity.

Even though sapphire and ruby nozzles can be relatively expensive compared to conventional materials, their longevity and durability make them the most cost-effective choice and justify the investment.

Benefits of sapphire and ruby are multiple:

- Precision: These nozzles are known for their accuracy in fluid dispensing, which is critical in many industrial processes.

- Durability: Their hardness and resistance to wear ensure a long service life, reducing the need for frequent replacements.

- Chemical Resistance: Both sapphire and ruby are chemically inert and can handle a wide range of fluids without corroding or degrading.

These precision fluid nozzles are typically custom designed for a client to meet specific application requirements. Their use can contribute to improved product quality, reduced maintenance costs, and increased efficiency in various industrial processes.

Inkjet Nozzle

Pierhor-Gasser inkjet nozzles are components that are placed in printing heads and used in inkjet printing technology. Their task is to dispense ink precisely and accurately onto various surfaces, such as paper, fabric, plastic, or other substrates.

The precision that our inkjet nozzles provide is especially important for high resolution printers, small character printers, as well as mobile printers and other marking systems used in industry that require maximum precision and flawless application.

Waterjet Nozzle

A waterjet nozzle is a versatile industrial tool for precision cutting, cleaning, surface preparation and machining a wide range of materials using high-pressure water and abrasive particles.

The size and shape of the orifice containing the nozzle impacts the flow, velocity, and accuracy of the waterjet stream therefore the quality and efficiency of the process itself.

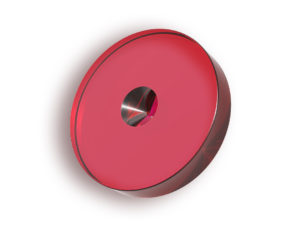

Saphire Waterjet Nozzle

The choice of nozzle and cutting parameters depends on the specific material being processed and the desired results. Pierhor-Gasser manufactures sapphire nozzle that is used to provide high pressure and high precision waterjet.

Tube Cleaning Carrier Heads

Specialized tube cleaning nozzles are employed to efficiently remove deposits, scale, or contaminants from the interior of tubes. They are designed to deliver high-pressure water or abrasive materials into the tubes, ensuring thorough cleaning.

Surface Blasting Carrier Heads

Waterjet nozzles for surface blasting are designed for high-pressure cleaning and surface preparation applications. They are used in conjunction with carrier heads, which hold and guide the nozzles over the surface being cleaned or blasted. These nozzles are engineered to deliver high-pressure water or abrasive materials to remove coatings, rust, contaminants, or other materials from various surfaces, such as metal, concrete, or stone.